Prestressing ASTM A416 Grade 270 7 Wire Rope PC Strand With 1860Mpa

Steel Grade:77B/82B

Place of Origin: Tianjin, China

Type:Drawn Wire

Alloy Or Not:Non-alloy

Special Use:Cold Heading Steel

Certificate:ISO9001

Standard: ASTM A416, BS 5896, prEN 10138 etc.

Surface treatment:Heat Treatment

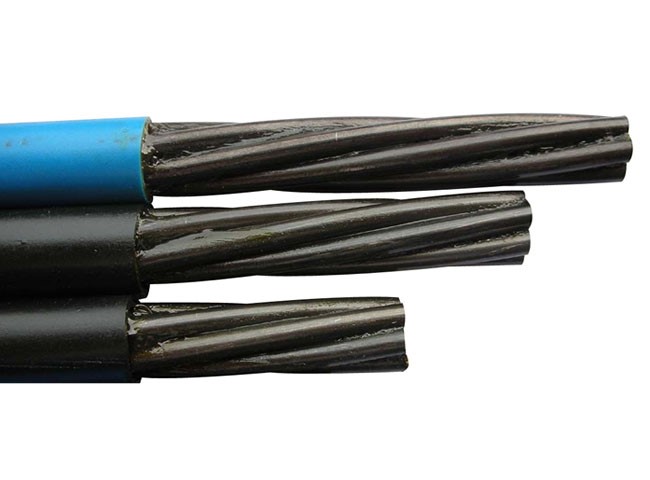

Structure:1X7

MOQ:25tons

Samples:Free sample is available to test quality.

Terms of payment: 30% T/T down payment, 70% T/T payable before loading

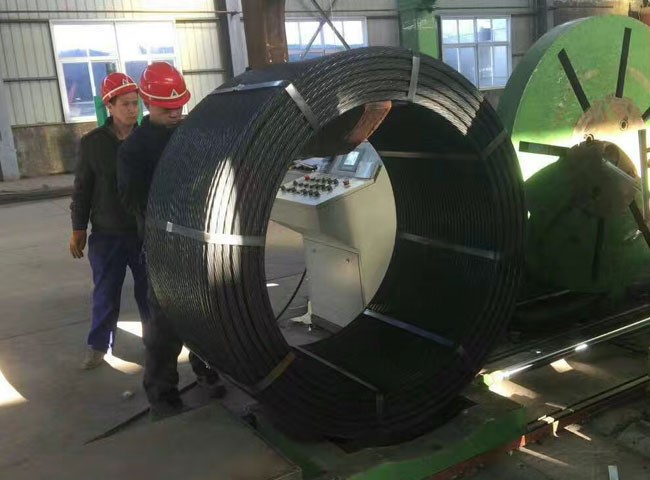

Packaging Details:Around 3 MTs per coil, and stripped by steel belts tightly, then warpped by PP woven clothes, and reinforced by supporting boards.

PE coated low relaxation PC strands are widely used in pre-tensioning or post tensioning prestressed concrete structure, like cable stay bride or PT slabs. It is characterized by having no need of room for future expansion and grout, convenient construction, material saving and easily bending etc.

We could offer international standards like ASTM A416, BS 5896, EN 10138 etc.

Coil weight is suitable for cutting around 1-3 tons, other coil weight available as well. Normally strand placed as eye-to-sky when loading. Each coils packed with steel strips and woven bag to protect the strand from damage.

Main Application:

Bridges, high-rise buildings, industrial facilities, warehouses, stadiums, sport complexes, containment tanks, airports, seaports, train stations, railways, subways, monorails, tunnels, dams, reservoirs, above and underground mining operations, foundations etc.

TRS is also capable of producing epoxy-coated strand, galvanized PC strand, PE zinc-coated strand, indented PC strand, spiral-rip PC strand, for various applications.

ASTM A416

|

Grade |

Nominal diameter (In) (mm) |

Diameter tolerant (mm) |

Steel area of strand (mm2) |

Nominal weight (kg/1000m) |

Minimum breaking strength (kN) |

Min. yield strength (kN) |

Min. elongation (Lo≥500mm) |

1000H Relaxation value %≤ |

||

|

Initial load is 70% nominal maximum load |

Initial load is 80% nominal maximum load |

|||||||||

|

250 |

0.375 |

9.53 |

±0.4 |

51.61 |

405 |

89.0 |

80.1 |

3.5% |

2.5 |

3.5 |

|

250 |

0.438 |

11.1 |

±0.4 |

69.68 |

548 |

120.1 |

108.1 |

3.5% |

2.5 |

3.5 |

|

250 |

0.500 |

12.70 |

±0.4 |

92.90 |

730 |

160.1 |

144.1 |

3.5% |

2.5 |

3.5 |

|

250 |

0.600 |

15.20 |

±0.4 |

139.35 |

1094 |

240.2 |

216.2 |

3.5% |

2.5 |

3.5 |

|

270 |

0.375 |

9.53 |

-0.15 +0.65 |

54.84 |

432 |

102.3 |

92.1 |

3.5% |

2.5 |

3.5 |

|

270 |

0.438 |

11.11 |

-0.15 +0.65 |

74.19 |

582 |

137.9 |

124.1 |

3.5% |

2.5 |

3.5 |

|

270 |

0.500 |

12.70 |

-0.15 +0.65 |

98.71 |

775 |

183.7 |

165.3 |

3.5% |

2.5 |

3.5 |

|

270 |

0.600 |

15.24 |

-0.15 +0.65 |

140.00 |

1102 |

260.7 |

234.6 |

3.5% |

2.5 |

3.5 |

BS5896

|

Type |

Nominal diameter (mm) |

Tolerance (mm) |

Steel area of strand (mm2) |

Nominal weight (kg/1000m) |

Tensile strength (kN) |

Min. breaking strength(kN) |

Specified Characteristic 0.1% yielding load |

Load at 1% Elongation Lo≥500mm |

Min. elongation (Lo≥500mm) |

Relaxation value 1000h %≤ |

||

|

60% Initial load |

70% Initial load |

80% Initial load |

||||||||||

|

7-wire standard |

9.3 |

+0.3/-0.15 |

52 |

408 |

1770 |

92 |

78 |

81 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire standard |

11.0 |

+0.3/-0.15 |

71 |

557 |

1770 |

125 |

106 |

110 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire standard |

12.5 |

+0.4/-0.2 |

93 |

730 |

1770 |

164 |

139 |

144 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire standard |

15.2 |

+0.4/-0.2 |

139 |

1090 |

1670 |

232 |

197 |

204 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire super |

9.6 |

+0.3/-0.15 |

55 |

432 |

1860 |

102 |

87 |

90 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire super |

11.3 |

+0.3/-0.15 |

75 |

590 |

1860 |

139 |

118 |

122 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire super |

12.9 |

+0.4/-0.2 |

100 |

785 |

1860 |

186 |

158 |

163 |

3.5% |

1.0 |

2.5 |

4.5 |

|

7-wire super |

15.7

|

+0.4/-0.2 |

150 |

1180 |

1770 |

265 |

225 |

233 |

3.5% |

1.0 |

||